In-Depth Analysis of Huawei’s Management Benchmarking Models

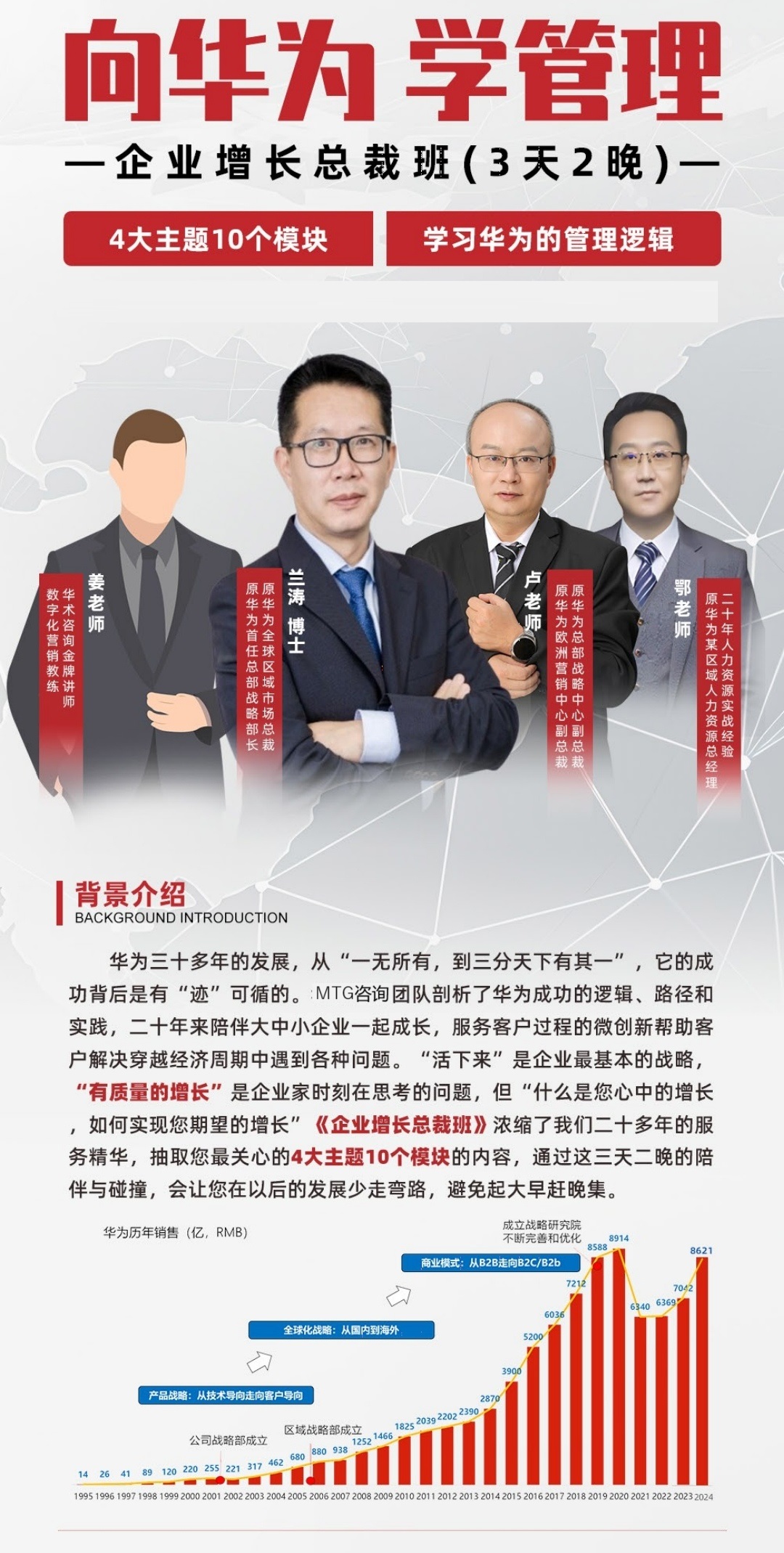

Huawei Technologies, founded in 1987 by Ren Zhengfei, has evolved from a modest telecommunications equipment distributor into one of the world’s most influential technology giants. Its rise is not merely attributed to innovation or market expansion but also to its sophisticated and disciplined management practices. Central to Huawei’s operational excellence is its strategic use of management benchmarking models—a systematic approach to measuring performance against global leaders and continuously improving internal processes. This article provides an in-depth analysis of Huawei’s benchmarking methodologies, their implementation across various organizational functions, and the resulting competitive advantages.

Foundations of Huawei’s Benchmarking Philosophy

At the core of Huawei’s management philosophy lies a deep commitment to continuous improvement and customer-centric innovation. The company adopts a long-term strategic vision that emphasizes learning from the best-in-class organizations worldwide. Rather than relying solely on internal metrics, Huawei actively benchmarks itself against leading global firms such as IBM, Ericsson, Motorola, and Apple. This external orientation allows Huawei to identify gaps in efficiency, quality, and innovation, enabling targeted enhancements.

Ren Zhengfei famously stated, “To learn from others is to shorten the path to success.” This mindset underpins Huawei’s benchmarking culture. The company does not view benchmarking as a one-time exercise but as an ongoing process embedded in its daily operations and strategic planning cycles.

Key Benchmarking Models Adopted by Huawei

1. IPD (Integrated Product Development)

One of the most significant benchmarking initiatives Huawei undertook was the adoption of the Integrated Product Development (IPD) model, inspired by IBM in the late 1990s. Before implementing IPD, Huawei faced challenges with product development cycles that were lengthy, inefficient, and often misaligned with market demands.

By studying IBM’s R&D processes, Huawei restructured its product development framework to emphasize cross-functional collaboration, stage-gate reviews, and concurrent engineering. The IPD model enabled faster time-to-market, reduced development costs, and improved product quality. For example, the time required to launch new telecom equipment was reduced by over 50%, significantly enhancing Huawei’s responsiveness to customer needs.

2. ISC (Integrated Supply Chain)

Another critical benchmarking effort was the transformation of Huawei’s supply chain through the Integrated Supply Chain (ISC) model, again modeled after IBM’s best practices. Prior to this reform, Huawei struggled with inventory inefficiencies, supplier coordination issues, and logistical bottlenecks.

The ISC initiative introduced advanced demand forecasting, vendor-managed inventory systems, and real-time logistics tracking. By aligning procurement, production, and distribution processes, Huawei achieved greater agility and cost control. This became particularly crucial as the company expanded globally, requiring seamless coordination across multiple continents and regulatory environments.

3. LTC (Lead to Cash)

To optimize its sales and service delivery processes, Huawei implemented the Lead to Cash (LTC) framework, which streamlines the entire customer engagement lifecycle—from lead generation to contract fulfillment and revenue recognition. Drawing insights from Western enterprise software companies, Huawei redesigned its front-end operations to enhance transparency, accountability, and customer satisfaction.

The LTC model integrates CRM systems, automated quotation tools, and project management platforms, ensuring that sales opportunities are managed efficiently and contracts are executed with minimal delays. This has been instrumental in Huawei’s ability to manage complex B2B deals, especially in large-scale infrastructure projects.

Organizational Culture and Employee Engagement

Benchmarking at Huawei extends beyond processes—it deeply influences corporate culture. The company fosters a performance-driven environment where employees are encouraged to seek best practices, challenge the status quo, and pursue excellence. Regular training programs, internal knowledge-sharing platforms, and cross-departmental rotations reinforce this culture of continuous learning.

Moreover, Huawei employs a rigorous performance appraisal system aligned with benchmarked KPIs. Employees are evaluated not only on individual output but also on their contribution to process improvements and innovation. This alignment ensures that benchmarking outcomes translate into tangible behavioral changes across all levels of the organization.

Challenges and Criticisms

Despite its successes, Huawei’s benchmarking journey has not been without challenges. One major concern is the high cost of transformation. Implementing models like IPD and ISC required substantial investment in consulting, technology, and change management. Smaller competitors may find such investments prohibitive, highlighting the resource advantage Huawei enjoys.

Additionally, some critics argue that excessive reliance on Western models risks cultural misalignment. While Huawei has adapted these frameworks to fit its unique context, there remains a tension between global standardization and local responsiveness—particularly in diverse international markets.

Furthermore, geopolitical pressures and trade restrictions have complicated Huawei’s access to certain technologies and partnerships, limiting its ability to benchmark against some industry leaders in specific domains, such as semiconductor design and software ecosystems.

Strategic Outcomes and Global Competitiveness

The impact of Huawei’s benchmarking initiatives is evident in its sustained growth and global footprint. By systematically adopting and adapting world-class management models, Huawei has achieved:

- A faster innovation cycle, allowing it to compete effectively in 5G, cloud computing, and AI.

- Operational resilience, demonstrated during global supply chain disruptions.

- Enhanced customer trust, due to consistent product quality and reliable service delivery.

- Stronger organizational scalability, supporting rapid international expansion.

These outcomes have positioned Huawei as not just a follower of global standards but increasingly as a benchmark setter in its own right—especially in emerging technologies and digital infrastructure.

Conclusion

Huawei’s management benchmarking models represent a masterclass in strategic learning and operational discipline. By rigorously analyzing and integrating best practices from global leaders, the company has transformed its internal capabilities and strengthened its competitive edge. While challenges remain, particularly in navigating geopolitical complexities and sustaining innovation under pressure, Huawei’s benchmarking journey offers valuable lessons for organizations aiming to achieve excellence in a rapidly evolving global landscape. The key takeaway is clear: sustainable success comes not from reinventing the wheel, but from learning how the best wheels are built—and then building them better.